Katargam, Surat, Gujarat

- GST NO. : 24CNKPS4030D1Z8

Microsilica Powder

| Business Type | Exporter, Supplier, Retailer, Wholesaler, Trader, Distributor, Importer |

| Country of Origin | India |

| Type | Silica Powder, India |

| Material | Natural Quartz, India |

| Click to view more | |

Preferred Buyer From

| Location | India ( Gujarat, Madhya Pradesh, Maharashtra, Rajasthan only) & All other countries |

Product Details

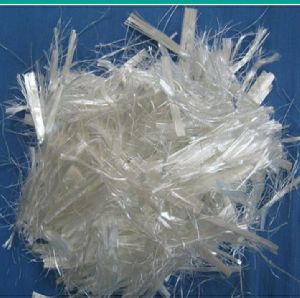

Micro Silica Micro Silica is designed to give a big Qualitative boost to Concrete. It is well recognizedthat Concrete Mix for High Strength cannot be achieved without some extra cementitiousmaterialbeyond Cement& Fly ash. HereMicro Silicaplays avital rolein ü IncreasingCompressive, Flexural andbondstrengthsinconcrete. ü ImprovestheLifeofConcreteby actingasCorrosionInhibitorforReinforcement. ü Improves the Life of Concrete by reducing Alkali-Silica Reaction (ASR)orConcrete Cancer. Micro Silica is a mineral admixture comprising of very fine solid glassy spheres of silicondioxide (SiO2). Micro Silica is fine amorphous silica with particle size around 100 timessmaller than averageparticlesizeofcement andflyash. HigherCompressive,Flexural&BondStrengthwithMicro Silica ü The silica present in Micro Silica, reacts with the weaker calcium hydroxide releasedduring the hydration of cement and forms additional calcium silicate hydrate (C – S –H). The concrete derives greater strength from higher concentration of strong CalciumSilicateHydrate replacingweak andeasily solublecalciumhydroxide. ü Micro Silica is like a pozzolanic material which provides more uniform distributionandagreatervolumeofhydrationinconcretestructures.ThischangestheRheologyofconcreteandreducesthewater-binderratio.Thisinturnresultsintohighercompressivestrength. ReinforcementCorrosionInhibitorroleofMicro Silica ü With particle size of 1/100thof cement & fly ash, Micro Silica drastically reducestheaveragesizeofporesintheconcrete.Thisdrasticallyreduceswaterpermeabilityinconcrete. ü Lower water-binder ratio achieved by adding Micro Silica ensure that the concretedoesnot loose waterduring setting and nopin holes are created. ü It reduces the rate of carbonation, decreases permeability to chloride ions and impartshighelectricalresistivity.Henceitprotectsthereinforcement steeland embedment. ü As an additional functional benefit, this reduces the instances of damp and waterleakagetroubles. ResistanttoConcreteCancer(Alkali-AggregateReaction) ü CementHydrationprocessproducesCalciumHydroxidealongwithSodiumandPotassiumoxides which has the followingimpacton concreteat a laterstage: § With age the porosity of concrete gathers sufficient moisture to aid a swellingreaction between highly alkaline cement paste and the reactive non-crystallinesilica found in many aggregates. This form hydroscopic gel of Sodium Silicatewhich swells absorbing further moisture weakening the concrete and creatingcracks. These cracks lead to increased porosity which in turn exponentiallypropagates the process of disintegration. That is the reason it is termed asConcreteCancer. § IncaseofSulfateattack,freecalciumhydroxidereactstoproducecalciumsulphate.This brings acidity inconcrete andweakens thestructure. ü Micro Silica acts with the policy of “fight Fire with Fire” to combat ASR reaction. Itinitiates a prompt reaction at early stage of concrete hardening. Thus, it binds thesetroublemakers, i.e.Calcium Hydroxide along with Sodium and Potassium oxides. Thus, they are arrested and quarantined notallowingthemtocreatemuchtroubleatlaterstage.AddtothisthefactthatMicro Silica has already reduced the porosity and hence curtailing the availability ofmoisture,theotherkey requirement for this process. Recommendation Micro Silica can be mixed between 5-10% of cement used in Concrete Mix for excellentperformance.

Looking for "Microsilica Powder" ?

Explore More Products