Katargam, Surat, Gujarat

- GST NO. : 24CNKPS4030D1Z8

Anti - Crack AR Glass Fiber

| Business Type | Exporter, Supplier, Retailer, Wholesaler, Trader, Distributor, Importer |

| Brand Name | ANTI CRACK HD. AR FIBER GLAS |

| Material | Glass |

| Weight | 25kg,85GM. |

| Click to view more | |

Preferred Buyer From

| Location | India ( Gujarat, Madhya Pradesh, Maharashtra, Rajasthan only) & All other countries |

Product Details

Grade

New

Color

White

Pattern

Siliconized

Fiber Length

6mm,12mm,18mm,24mm,36mm,3MM

Packaging Type

Loose,25kg

Fiber Type

Chopped Strands

Country of Origin

India

Eco-Friendly

Yes

Packaging Size

10-20Kg,85GM.

Usage

Concrete

Specialties

Eco-Friendly,Heat-Resistant

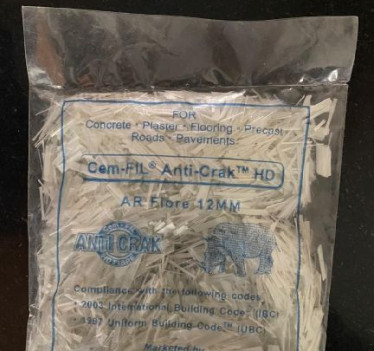

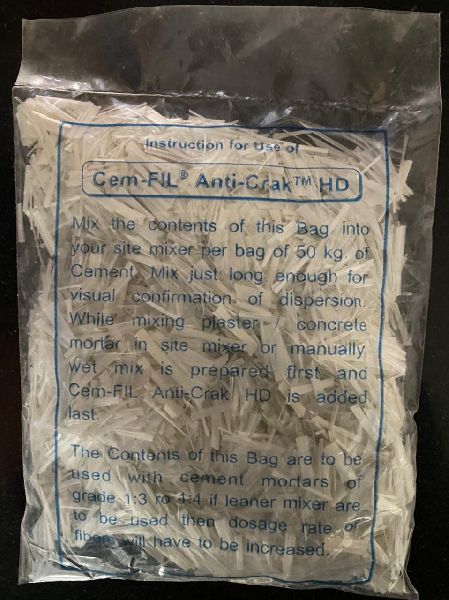

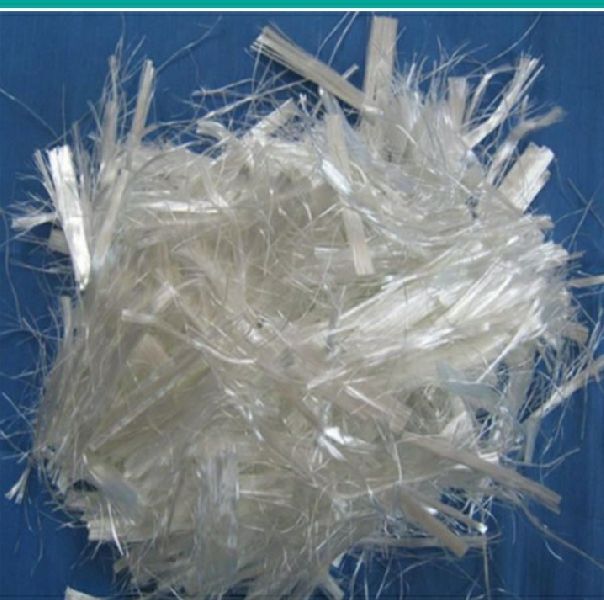

Anti-Crack HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.Anti-Crack HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.They incorporate easily into mixes creating a multidimensional homogeneous network of reinforcement in the matrix.Anti-Crack?? HD fibres can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.Quality Standards Certification:Fibres can be introduced directly in the ready mix plant or directly in the concrete truck. Recommended dosage is 600 g/m3 (1 lb/cum) of concrete to control plastic shrinkage cracking Anti-Crak HD fibres are packed in individual paper bags (water dispersible) or in plastic bags.Anti-Crak HD fibres should be stored away from heat and moisture, and in their original packaging.The best conditions are:Anti-Crak HD fibres do not protrude through the surface and require no additional finishing procedures.The reinforcement is incorporated in the concrete mass and is invisible on the finished surface.High dispersion (220 million filaments per kg, 100 million per lb)Excellent workabilityInvisible on the finished surfaceDoes not corrodeControl and prevention of cracking in fresh concreteOverall enhancement of durability and mechanical properties of concreteEffective at very low dosageHomogeneous mixSafe and easy to handleLoss on Ignition: 0.55% (ISO 1980: 1980)Moisture: 0.3% max (ISO 3344: 1977)Material: Alkali Resistant Glass*Specific Gravity: 2.68 g/cm3Electrical Conductivity: Very lowChemical Resistance: Very highModulus of elasticity: 72GPa – 10 x 106 psiTensile Strength: 1,700 MPa – 250 x 103 psiAnti-Crak HD fibres are part of Cem-FIL product range

PRODUCT DESCRIPTION ADVANTAGES AND BENEFITS FEATURES (nominal values)PRODUCT APPLICATIONAnti-Crak HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.Anti-Crak HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.They incorporate easily into mixes creating a multidimensional homogeneous network of reinforcement in the matrix.Anti-Crak?? HD fibres can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.-Anti-Crak HD fibres do not protrude through the surface and require no additional finishing procedures. -The reinforcement is incorporated in the concrete mass and is invisible on the finished surface.-High dispersion (220 million filaments per kg, 100 million per lb)-Excellent workability- Invisible on the finished surface- Does not corrode -Control and prevention of cracking in fresh concrete- Overall enhancement of durability and mechanical properties of concrete- Effective at very low dosage- Homogeneous mix- Safe and easy to handle- Fiber length: 12 mm - Filament diameter: 14m, (0.000546 in)- Loss on Ignition: 0.55% (ISO 1980: 1980)- Moisture: 0.3% max (ISO 3344: 1977) Material: Alkali Resistant Glass* Specific Gravity: 2.68 g/cm3 Softening point: 860??C - 1580??F-Electrical Conductivity: Very low-Chemical Resistance: Very highModulus of elasticity: 72GPa - 10 x 106 psi-Tensile Strength: 1,700 MPa - 250 x 103 psi* Anti-Crak HD fibres are part of Cem-FIL product rangeQUALITY STANDARDS CERTIFICATIONFibres can be introduced directly in the ready mix plant or directly in the concrete truck.Recommended dosage is 600 g/m3 (1 lb/cum) of concrete to control plastic shrinkage crackingAnti-Crak HD fibres are packed in individual paper bags (water dispersible) or in plastic bags.Anti-Crak HD fibres should be stored away from heat and moisture, and in their original packaging.The best conditions are:- Temperature: 15C - 35C.- Humidity: 35% - 65%.Hear I provide you a Price for your Demanded product quality.Anti-Crak 25. KG BAGS

PRODUCT DESCRIPTION ADVANTAGES AND BENEFITS FEATURES (nominal values)PRODUCT APPLICATIONAnti-Crak HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.Anti-Crak HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.They incorporate easily into mixes creating a multidimensional homogeneous network of reinforcement in the matrix.Anti-Crak?? HD fibres can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.-Anti-Crak HD fibres do not protrude through the surface and require no additional finishing procedures. -The reinforcement is incorporated in the concrete mass and is invisible on the finished surface.-High dispersion (220 million filaments per kg, 100 million per lb)-Excellent workability- Invisible on the finished surface- Does not corrode -Control and prevention of cracking in fresh concrete- Overall enhancement of durability and mechanical properties of concrete- Effective at very low dosage- Homogeneous mix- Safe and easy to handle- Fiber length: 12 mm - Filament diameter: 14m, (0.000546 in)- Loss on Ignition: 0.55% (ISO 1980: 1980)- Moisture: 0.3% max (ISO 3344: 1977) Material: Alkali Resistant Glass* Specific Gravity: 2.68 g/cm3 Softening point: 860??C - 1580??F-Electrical Conductivity: Very low-Chemical Resistance: Very highModulus of elasticity: 72GPa - 10 x 106 psi-Tensile Strength: 1,700 MPa - 250 x 103 psi* Anti-Crak HD fibres are part of Cem-FIL product rangeQUALITY STANDARDS CERTIFICATIONFibres can be introduced directly in the ready mix plant or directly in the concrete truck.Recommended dosage is 600 g/m3 (1 lb/cum) of concrete to control plastic shrinkage crackingAnti-Crak HD fibres are packed in individual paper bags (water dispersible) or in plastic bags.Anti-Crak HD fibres should be stored away from heat and moisture, and in their original packaging.The best conditions are:- Temperature: 15C - 35C.- Humidity: 35% - 65%.Hear I provide you a Price for your Demanded product quality.Anti-Crak 25. KG BAGS

Looking for "Anti - Crack AR Glass Fiber" ?

kilogram

Explore More Products